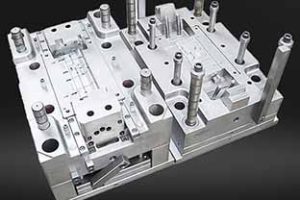

Common plastic mold problems and solutions for Shenzhen Donglai Precision Mold Co., Ltd

1 Injection Mold in Plastic Product Processing – Methods to Prevent Mold Cracks

The causes of cracks in plastic molds

1. Lack of rigidity in injection molds

2. Stress convergence of injection mold cavity spear head

2、 Knowledge related to injection molds

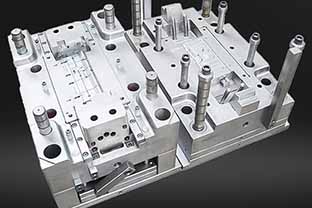

1. The wall thickness planning of injection molds is an important parameter in mold planning, which requires strength calculation (simple tension calculation) to ensure the necessary thickness of the mold. Additionally, additional grooves are added to utilize the overall rigidity of the mold

2. When processing the spear head of the injection mold cavity, stress convergence is prone to occur, and cracks are also prone to occur in this area. Therefore, it is necessary to process the spear head into a shape with a rounded corner R

3、 Solution

1. Process the spear head of the injection mold cavity into a shape with a rounded angle R, and strengthen it by processing it into a groove shape on the mold parting surface to enhance the rigidity of the mold

4、 Due to differences in materials;

1. There is no special reason

Injection Mold in Plastic Product Processing – Methods to Prevent Mold Stickiness and Bending The Reason for Mold Stickiness and Bending in Injection Mold is Lack of Mold Rigidity

2. Due to the expansion of the injection pressure mold, the related knowledge cavity will expand to some extent due to the effect of the injection pressure. Assuming that the mold is restored to its original state, but in reality, the pressure inside the mold still maintains a high state, causing the product to cool and solidify. When the mold is restored to its original state, a large force is applied to the mold, causing it to have to open slightly. Solution:

3. Immediate: Handle the ejection pressure and do not increase it above the set value. Long term: Set grooves and force adjustments. Due to differences in materials;

4. Tie your hands to materials with high rigidity.

5、 Refer to the instructions;

1. Due to the simplicity of testing plastic molds, a dial gauge is attached to the mold to monitor and slowly increase the injection pressure. This method is more effective.

2. The plastic mold that experiences viscosity and swelling is disassembled from the injection machine, and the product is softened by heating before being removed.

3. Due to the lack of rigidity in the plastic mold, it is reinforced and clamped from the outside using a clamping plate.