Outlook for Donglai Precision Mold: Plastic Injection Mold is Full of Vitality in 2025

Since 2022, our plastic injection mold exports have been continuously increasing, and our competitiveness has also improved. Currently, our plastic injection mold trading market is very large, and it is still increasing at a rate of 13% to 19% annually. This is mainly due to our expansion into plastic injection mold users such as sedans, home appliances, IT industry, packaging, building materials, and daily necessities. According to statistics from Xiang Mold Company, the output value of our plastic products in 2022 is close to 800000 tons, and it is still continuously increasing. This shows that domestic demand has a huge driving force on the plastic injection molds of our mold factory.

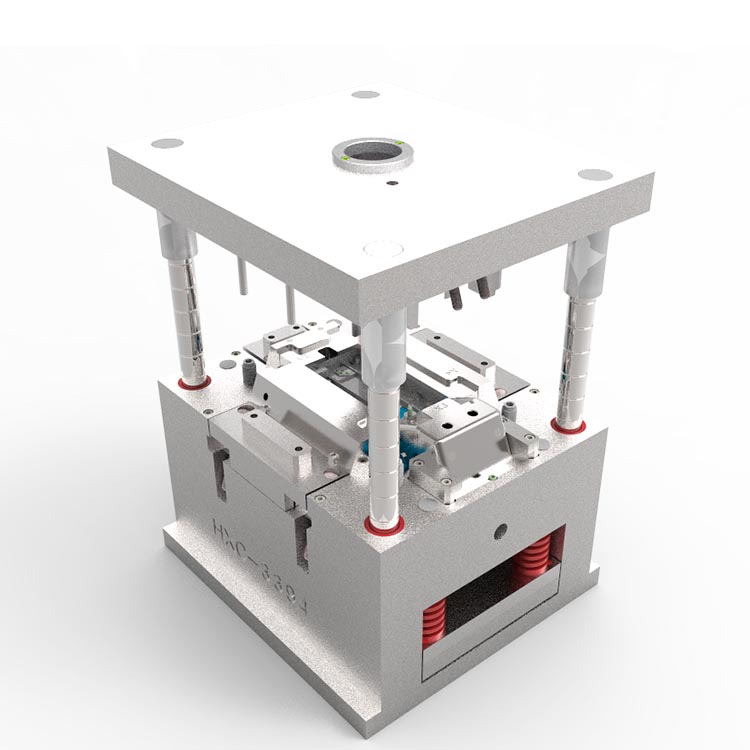

Plastic injection mold is a type of plastic injection mold used to produce plastic products. It consists of several sets of parts, each with a molding cavity inside. During injection molding, the plastic injection mold is clamped onto the injection molding machine, and the molten plastic is injected into the mold cavity, cooled and shaped inside the cavity. Then, the upper and lower molds are separated, and the product is ejected from the plastic injection mold through the ejection system. Finally, the mold is closed for the next injection molding, and the entire injection molding process is cyclic.

Outlook for Donglai Precision Mold,Plastic Injection Mold is Full of Vitality in 2025

More than 90% of car manufacturing processes require the use of plastic injection molds, while over 90% of plastic products are formed using plastic injection molds. Many plastic components in the IT industry also require plastic injection molds. Looking ahead to precision molds, these inherent demands are continuously driving the development of plastic injection molds in China. Affected by various national policies and the continuous expansion of market space, the development of professions such as sedans, IT industry, and packaging has been very rapid in recent years. Not only has there been significant development in production capacity, but there has also been significant progress in the high-end aspects of these industries. Therefore, these industries have strong demand for plastic injection molds in the three aspects of high, medium, and low end. Driven by high-tech and the demand for pillar industries, plastic injection molds in China have formed a huge industrial chain. From the upstream raw and auxiliary materials industry and processing, testing equipment to downstream industries such as machinery, cars, motorcycles, household appliances, electronic communication, and construction materials, the prospects of plastic injection molds are full of vitality

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.

Requesting a reward, your tipping is my motivation

https://paypal.me/molddl?country.x=C2&locale.x=zh_XC