Important Development Direction of Injection Mold Processing and Mold Processing Technology in 2025

Modern injection mold manufacturing technology is moving towards accelerating information driven, advancing manufacturing flexibility, active manufacturing, and systematic integration. Specifically, it is reflected in the CAD/CAM technology of molds, laser rapid prototyping technology of molds, precision forming technology of injection molding molds, ultra precision machining technology of molds, dynamic imitation technology of activities, cooling, and heat transfer processes using finite element method and gap element method in mold planning, CIMS technology of molds, advanced manufacturing technologies such as DNM technology and CNC technology that have been developed.

1. High speed milling: third-generation mold making technology

High speed milling not only has high machining speed, good machining accuracy and surface quality, but also has lower temperature rise (machining workpiece only increases by 3 ℃) and smaller thermal deformation compared to traditional cutting. Therefore, it is suitable for processing temperature and thermal deformation active materials (such as magnesium alloys); Also, due to its small cutting force, it is suitable for machining thin-walled and poorly rigid parts; Reasonable selection of cutting tools and cutting parameters can achieve a series of advantages such as machining hard materials (HRC60). Luo Baihui stated that high-speed milling technology was still a hot topic at that time, and it had been developed towards higher levels of flexibility, intelligence, and integration, becoming the third generation of mold making technology.

2. EDM milling and “green” product technology

From the perspective of foreign electrical machining machine tools, regardless of their functions, process indicators, intelligence, and proactivity, they have reached an appropriate high level. The new trend in foreign countries is to conduct research and development on electrical discharge milling technology (electrical discharge generative machining technology), which is a new technology that replaces the traditional use of formed electrodes to process cavities. It uses high-speed rotating simple tubular electrodes for three-dimensional or two-dimensional summary processing (like CNC milling), so there is no longer a need to manufacture messy formed electrodes. This is clearly a serious development in the field of electrical discharge forming machining.

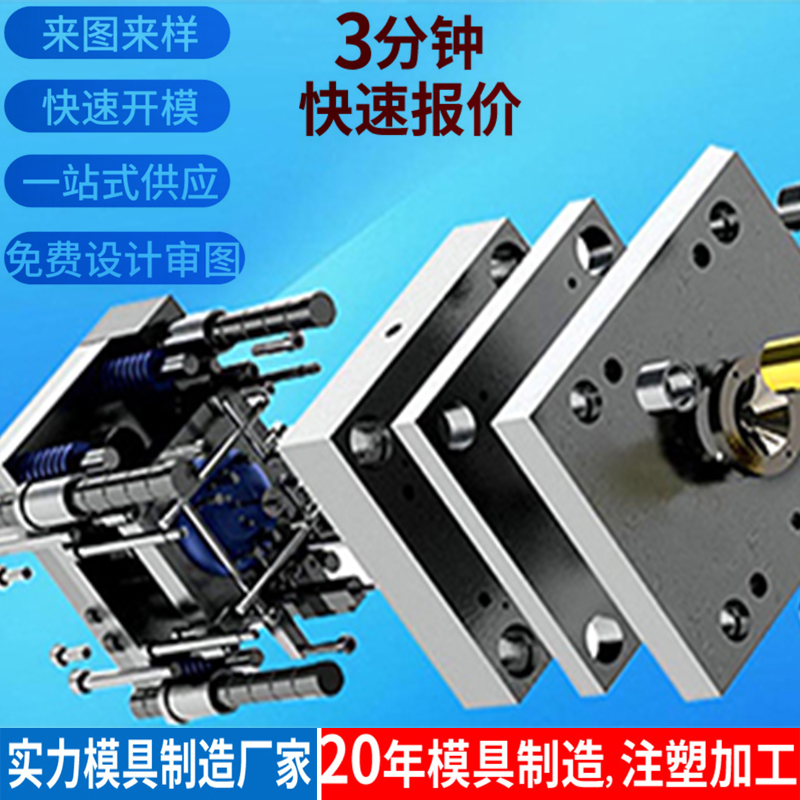

Injection Mold Processing and Mold Processing Technology

Mitsubishi Corporation of Japan has launched the EDSCAN8E electric discharge machining machine tool, which has made new developments. This function can actively compensate for electrode loss. A dedicated CAM system developed for this machine on Windows 95 can be linked with general CAD systems such as AutoCAD, and can perform online precision measurement to ensure the completion of high-precision machining. In order to confirm whether the machining shape is abnormal or damaged, the CAM system can also complete simulation machining.

Along with the advancement of electrical discharge machining technology, the safety and protection technologies of electrical discharge machining are increasingly being paid attention to, and many electrical machining machines have considered safety protection technologies. Nowadays, the European Community has stipulated that machine tools without the “CE” mark cannot enter European Community shopping malls, and international shopping malls are increasingly paying attention to safety protection technology requirements.

Nowadays, the primary problem with electrical discharge machining (EDM) machines is radiation interference. Due to its significant impact on safety and environmental protection, and the increasing emphasis on “green” products in international shopping malls, the “green” product technology of EDM machines, as the leading equipment for mold processing, will be a necessary challenge to be addressed in the future.

3. New Generation Mold CAD/CAM Software Technology

Nowadays, mold software developed by universities and research institutes in countries such as the UK, the US, Germany, and China has the characteristics of intelligence, integration, and manufacturability evaluation of the new generation of mold CAD/CAM software. Luo Baihui stated that the new generation of mold software should be built on many knowledge summarized from mold planning practice. These knowledge have been systematically and scientifically organized, stored in an engineering knowledge base in specific methods, and can be easily accessed by molds. With the support of intelligent software, mold CAD is no longer an imitation of traditional planning and calculation methods, but under the guidance of advanced planning theory, and by making full use of the rich knowledge and successful experience of experts in this field, its planning results must be reasonable and progressiveness.

alll thee time i used too read smallper posts

whic as well clear their motive, annd that is alsoo happening

with this poswt whifh Iamm reasing att tnis place.

Requesting a reward, your tipping is my motivation

https://paypal.me/molddl?country.x=C2&locale.x=zh_XC