Around 2022, China will have the world’s largest demand for plastic mold processing in home appliances

With the rapid development of China’s economy in 2021, the demand for home appliances in shopping malls has also increased rapidly. As a result, the demand for plastic mold processing in our precision mold company’s home appliances has grown rapidly. Currently, as a global producer of household appliances, the plastic mold processing of household appliances is constantly expanding, leading to an increase in the demand for bulk raw materials in the household appliance industry.

The processing of many metal and plastic components used in household appliances has rapidly increased the demand for plastic mold processing in machine tools and household appliances. Many board and chip components used in household appliances have a special demand for the machine tool industry, namely large quantity and high speed. Various CNC punching machines are one of the important machine tools for professional processing of household appliances.

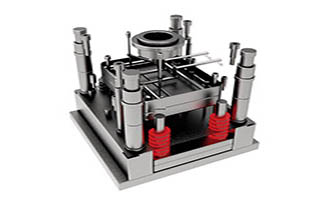

plastic mold processing in home appliances

Currently, many users are inclined to use CNC composite punching and shearing machines (which can form CNC punching and shearing composite flexible processing lines), but the demand for CNC punching machines in the market is still very high. They are mainly used for processing plate punching parts with various standardized hole types. There is a wide range of markets in the processing profession of large electrical control cabinets, and they can also be used for processing other large quantities of plate punching parts. The CNC punching and shearing composite machine can complete the punching, forming, and shearing of sheet metal in one go, especially suitable for sheet metal processing with subsequent bending processes. Multiple processes share a set of CNC system, hydraulic system, and feeding manipulator, which can be compared with the single machine connection of CNC punching and angle shearing machines. This not only reduces equipment investment, saves land area, and reduces failure rate, but also serves as a host to form a punching and shearing composite flexible processing line.

The growing demand for plastic mold processing in household appliances has also rapidly formed a complete industrial chain. Shenzhen Donglai Precision Mold is also continuously improving its plastic mold processing and process skills in the home appliance plastic mold processing industry chain, in order to better serve new and old customers