What is a plastic mold and what are the problems to pay attention to in the design of plastic molds?

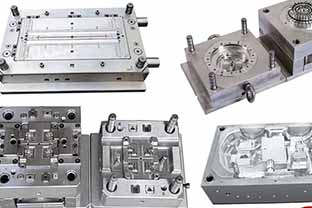

Plastic mold is a short for a combined plastic mold used for compression, extrusion, injection, blow molding and low foam molding. In the design of plastic molds, there are some important issues that need attention.

1. The glue inlet should be opened in the thick part of the product to ensure that the mold filling is smooth and complete.

2. The glue inlet should be opened as much as possible in a position that does not affect the appearance and function of the product. Usually, you can choose to be at the edge or bottom. Near the gate, a pull rod is usually set next to the cold hole to facilitate the demoulding of the channel. For large or flat products, it is recommended to use multi-point pouring to prevent warping, deformation and lack of materials.

3. The position of the gate should be selected in the place where the plastic mold filling process is the shortest, so as to reduce pressure loss and facilitate mold exhaust. Gates should be avoided near the slender core to avoid the direct impact of the material flow on the core, resulting in deformation, misalignment or bending.

4. In the design of plastic mold, factors such as gate size, mold flow analysis, and pouring mode in one mold and multiple holes also need to be considered. When choosing a cooperative manufacturer, you should also pay attention not only to the price, but also to comprehensively consider the quality, cycle and service. Mold manufacturers should have high-precision CNC machine tool processing equipment and use CAD/CAE/CAM mold technology for design and analysis. For molds with high accuracy requirements, it may be necessary to adopt advanced processes such as hot runer and gas-assisted molding.

5. Avoid multi-head collaboration and try to realize the one-stop service of plastic mold production and product processing. Even with qualified molds, good forming processing is required to produce batches of qualified products. Therefore, when choosing a partner, it is best to choose a partner that can provide a one-stop service to avoid the problems caused by long-head collaboration.

Plastic mold design needs to comprehensively consider various factors and work closely with the mold manufacturing unit to ensure that the designed products can be produced smoothly and the quality is stable and reliable. When choosing a partner, in addition to the price, we should also pay attention to quality, cycle and service to achieve the final production goal.