Important Development Direction of Injection Mold Processing and Mold Processing Technology in 2024

4. Advanced Rapid Injection Mold Manufacturing Technology

(1) The rapid development of laser rapid prototyping technology (RPM) has reached the international level in China and gradually completed commercialization. The world’s most commercialized rapid prototyping processes include SLA (Stereolithography), LOM (Layered and Split Manufacturing), SLS (Selective Laser Sintering), and 3D-P (3D Printing).

Tsinghua University has introduced the SLA250 (Stereolithography or photosensitive resin laser curing) equipment and technology from an American 3D company and conducted research and development. After several years of hard work and multiple improvements, it has improved and launched the “M-RPMS – Multi functional Rapid Prototyping Manufacturing System” (with Layered Solid Manufacturing SM and Melt Kneading Forming MEM). This is the only system in the world with independent intellectual property rights in China that has two types of rapid prototyping processes (national patents), and has a good cost-effectiveness ratio.

(2) Mouldless multi-point forming technology is another advanced manufacturing technology that uses a highly adjustable punch collective to replace traditional molds for sheet metal surface forming. The mold free multi-point forming system uses CAD/CAM/CAT technology as the primary method to quickly and economically complete the active forming of three-dimensional surfaces. Jilin University of Technology has undertaken a national key scientific and technological research project on dieless forming, and has independently planned and manufactured dieless multi-point forming equipment with international leading level.

Compared with the Massachusetts Institute of Technology in the United States, the University of Tokyo in Japan, and Tokyo Institute of Technology in Japan, this technology in our country is in a leading position in theoretical research and practical application, and is now being promoted and applied. 3. The resin stamping mold was successfully applied for the first time in the trial production of domestic sedans. FAW Mold Manufacturing Co., Ltd. has planned and manufactured 12 sets of resin molds for the modified trial production of the all-new Xiaohongqi sedan. These 12 sets of molds are respectively drawing molds for large, messy internal and external cover parts such as the luggage compartment, engine hood, front and rear left and right fenders. The main feature is that the mold surface is based on the main model processed by CAD/CAM, and high-strength resin from Swiss Ciba Precision is used for casting and forming. The gap between the convex and concave molds is precisely controlled by imported special wax sheets. The size accuracy of the molds is high, and the manufacturing cycle can be shortened by half to two-thirds. The manufacturing cost can be saved by about 10 million yuan (12 sets of molds). This has opened up a new path for the trial production and small-scale production of sedans in China, which is a pioneering initiative in China. Experts from Swiss Ciba Refining believe that it can reach the international level of the 1990s.

5. On site injection mold inspection technology

The development of precision molds requires increasingly high requirements for measurement. Fine coordinate measuring machines have long been limited by the environment and are rarely used on production sites. The new generation of three coordinate measuring machines basically have temperature compensation and the use of anti vibration data, improving dust prevention methods, improving environmental adaptability and application reliability, making it easy to use equipment in the workshop to achieve the characteristics of on-site measurement.

6. Mirror Polishing Technology for Mold Surface Engineering

The data of the high gloss polishing surface mold is not only a matter of chemical composition, but more importantly, a series of advanced processes such as vacuum degassing, argon gas protection of ingots, vertical continuous casting and rolling, and flexible forging are required during smelting, so that the mirror surface mold steel has a series of advantages such as fewer internal defects, fine impurity particle size, high dispersion degree, fine metal grain size, and good uniformity, in order to achieve the requirements of polishing to the mirror surface mold steel.

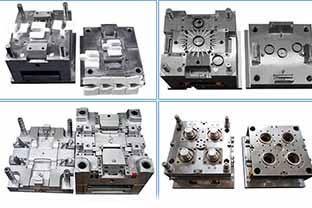

The design of plastic injection molds may seem simple, but in reality, there are many issues to be aware of during the design process. And it requires a lot of experience and technical accumulation. Donglai Fine Mold is an excellent plastic mold design and manufacturing company. With multiple professional plastic injection mold designers, we can provide reliable support for every customer’s design. When purchasing plastic molds, choose Donglai Fine Mold, which has a reasonable price and perfect after-sales service. When purchasing plastic molds, assuming you can choose a good company, it can reduce a lot of purchasing time, and after all, the selected products will also be very good. There are many companies to choose from in the shopping mall, but many customers directly choose Donglai Fine Mold. A very excellent enterprise that produces plastic molds can provide one-stop services from the initial planning to the final products, bringing a lot of convenience to customers. Since its establishment, Donglai Fine Mold has attached great importance to the production of various types of molds, and its own advantages are very good. When customers purchase plastic molds, they always attach great importance to the price. Donglai Fine Mold has always been very familiar with customer needs, and through years of hard work, can provide customers with products at very suitable prices. It is precisely because of this that tuning in homework has a very large living space. At the same time, there is a fierce competition in plastic mold operations, and Donglai Fine Mold has a very complete after-sales system. It’s not that after selling the product to the customer, there won’t be any other problems. The after-sales service is better handled, and we can maintain a good cooperative relationship with existing customers. Moreover, there will be a better impact on future cooperation.