Precision plastic mold manufacturers share that these three tasks

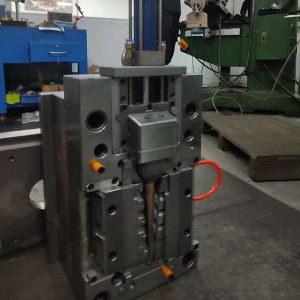

Many people know about the job of injection molding, and this step is very important for molds. Different mold quality can also lead to differences in the quality of finished products. However, it does not mean that high-quality products do not need to pay attention to maintenance work in the later stage. Therefore, in order to ensure that the effect of injection molding molds can be better, we need to do the following work.

1、 Regular inspection, maintenance, and refueling.

Generally speaking, the working cycle of injection molds is mostly between one month and several months, which requires a long time. Therefore, in addition to normal shift changes, operators should also explain the usage of injection molds. Detailed records of injection molds and their usage frequency, time, problems, malfunctions, inspection and maintenance results, etc., enable operators to have a detailed understanding of the relevant information of injection molds and ensure normal operation.

2、 Timely clean up the waste and dirt generated during the injection molding process

During the injection molding process, it is inevitable that various types of garbage and dirt will appear. If they accumulate more than once, it will affect the normal injection molding process and even have adverse effects on the injection molding results. Therefore, we should regularly clean the injection mold. In addition, for the pattern surface of the cavity injection molding mold polishing process, we should also shorten the cleaning interval appropriately to ensure a bright and clean cavity surface

Precision plastic mold manufacturers share that these three tasks cannot be ignored when processing injection molds

3、 The auxiliary components of injection molds should also be regularly inspected

In the maintenance process of injection molds, many people neglect the maintenance of auxiliary components of injection molds, which is not advisable. The auxiliary assembly of injection molds is also closely related to the effectiveness of injection molding processes. Therefore, it is also necessary to regularly check the auxiliary system of injection molds to ensure their normal use.

Precision plastic mold manufacturers can effectively address the issue of bubbles in injection molds through the above methods, improving product quality and production efficiency. In actual production, it is necessary to choose appropriate processing methods based on specific situations and continuously improve the process to ensure smooth processing of the product.

We have strong research and development capabilities and are a trusted manufacturer. Welcome to call or sales@molddl.com Consultation, our company supports small batch customization, packaging design, and free sample processing. Please contact us! Please indicate the source of the article when reprinting: http://www.molddl.com ,