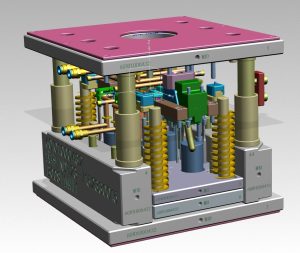

Plastic mold factory injection mold engineering plays an important role in the production of plastic products

Injection mold engineering plays an important role in the production of plastic products, by using technology to turn plastic into workpieces, whose structure and quality directly affect the quality of the finished product. However, in the work of injection molds, some problems are often encountered. Firstly, difficulty in removing material from the gate is a common issue. During the injection molding process, the grid adhesive sleeve is prone to sagging, leading to cracks and damage to the item. Operators must use copper to knock from the nozzle head, which affects production efficiency. The main reason may be the difference in the end point of the tapered hole and the material being too soft, which leads to deformation or damage of the tapered hole. Secondly, the difficulty standard for gate sleeve processing should be adopted, and special reamers should be used to address this issue.

Secondly, damage to the guide column is also a common problem. The guide column mainly plays a guiding role in the mold to ensure that the forming surfaces of the core and cavity do not collide. In different situations, the dynamic mold may generate lateral horizontal displacement force during injection, especially when the wall thickness of the plastic part is required to be uneven or when the side reaction of the plastic part is asymmetric.

Finally, bending of the moving template is also a common issue. During the injection molding process, reverse pressure may be generated inside the mold cavity, but many workers often overlook this, resulting in the finished product not meeting the expected results. The reverse pressure generated by the molten plastic inside the mold cavity is relatively high, usually between 600-1000 kg/cm. Mold manufacturers sometimes change the design dimensions or use low-strength steel plates instead of dynamic templates, resulting in template bending. Therefore, attention should be paid to these issues and corresponding measures should be taken to ensure the smooth operation of injection molds.