injection mold, what are the eight categories of injection molds?

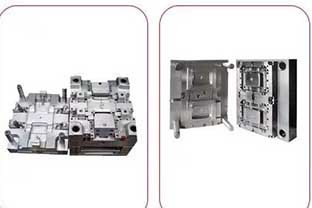

Injection molds are indispensable tools in the production of plastic products. They have a variety of categories, and each type has its own unique design and application. This article will introduce the eight categories of injection molds in detail.

1. Single-divided surface injection mold is one of the simplest forms of injection mold. When opening the mold, the moving mold and the fixed mold are separated to remove the plastic parts. This kind of mold, also known as a double-plate mold, can be designed as a single cavity injection mold or a multi-cavity injection mold according to needs. It is one of the most widely used injection molds.

2. The double-forming surface injection mold has two split surfaces, and its structure is more complex than the single-formed surface mold. An intermediate plate, also known as the movable gate plate, is added to the molding part, which is used for the injection mold of a single cavity or multi-cavity injection mold for pointing the gate feeding. When opening the mold, the middle plate is separated from the fixed template to remove the condensate of the pouring system. However, due to its complex structure and high manufacturing costs, it is generally not used for the molding of large or extra-large plastic products.

3. It is an injection mold with a lateral typing and core pulling mechanism. When the plastic part has side holes or side concaves, it needs to be molded with a moveable core or slider. After the moving mold moves down, the inclined section of the bending pin forces the slider to move, and the push rod pushes the push plate to remove the mold.

4. Injection molds with moving molding parts require the establishment of movable molding parts, such as movable convex molds, movable concave molds, etc. These parts can be removed from the mold together with the plastic parts when they are unmolded.

5. The self-removing thread injection mold is suitable for plastic parts with threads. Thread cores or rings that can be rotated can be set up. Using the mold opening action or the rotation mechanism of the injection molding machine, it can drive the thread core or threaded ring to rotate, so as to take off the plastic parts.

6. The runner-free injection mold adopts the method of adiabatic heating of the runner to keep the plastic in a melting state, so that there is no pouring system condensate when the mold is opened to take out the plastic part. Among them, adiabatic runner injection mold and hot runner injection mold are two common types.

7. The right-angle injection mold is suitable for the angle injection molding machine, and the direction of the feed is perpendicular to the direction of the opening and closing mold. The mainstream channel is opened on both sides of the dynamic and fixed die split surface, and replaceable runner inserts can be set at the end.

8. The demoulding mechanism is installed on the injection molding side of the mold, which is conducive to the work of the top-out device of the injection molding machine. Some plastic parts of special shapes need to set up a molding mechanism on the molding side so that the plastic parts can be molded.

Generally speaking, there are many categories of injection molds. Each type has its own specific design and application, which can meet the production needs of different plastic products. By understanding these eight categories, you can better choose injection molds suitable for your own production needs to improve production efficiency and product quality.