Plastic mold manufacturers should pay attention to common issues in injection mold processing

Date: 2024-07-01

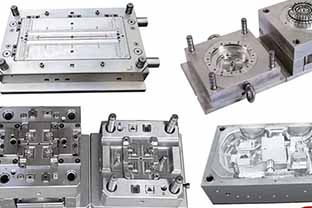

Injection molds are a crucial part of the injection molding process, and their quality and design directly impact the final product’s molding effect and quality. Therefore, attention to a series of issues is necessary in the injection mold manufacturing process to ensure the mold meets quality and performance requirements. This article will detail the issues to be aware of and common problem-solving methods in injection mold manufacturing.

Firstly, injection mold manufacturing usually takes a considerable amount of time, typically requiring about a month for a mold set to be opened, with more complex molds taking longer. Before opening a mold, a detailed review and approval process must be conducted to ensure the mold design meets requirements. Once the mold is manufactured and opened, testing is necessary to verify its performance and quality.

Key issues to note during injection mold manufacturing include:

1. Cooling system design in the mold:

The cooling system in the mold significantly affects factors such as product size, shape, plasticity, and holding pressure time. Well-designed cooling systems can enhance production efficiency and product quality.

2. Mold surface roughness:

The mold cavity’s surface roughness should be at a “mirror level” to ensure easy product demolding. Otherwise, excessive force may be needed for product ejection, risking product damage.

3. Mold rigidity and stability:

Molds should have sufficient rigidity to prevent deformation during the injection process. Simultaneously, choosing reasonable injection molding paths and exhaust positions ensures material reaches every part uniformly.

4. Injection mold fixation:

The method of fixing injection molds to injection machines should be reasonable and reliable to prevent displacement accidents during production. Easy disassembly is also an important consideration.

5. Proper demolding method:

Select suitable demolding methods and ejector pin positions to ensure products remain undamaged during demolding.

During injection mold processing, it is essential to consider materials, design, processing, testing, and other factors comprehensively to produce high-quality plastic products. Strict quality control at every stage is necessary to meet requirements. This article hopes to be helpful in addressing problems and solutions during injection mold manufacturing.