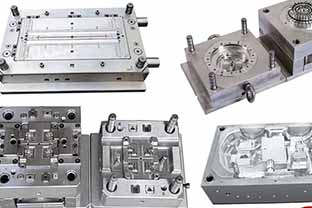

Production process and process of plastic mold customization

The production process and process of injection mold customization is a complex and delicate process, which requires the close cooperation of multiple links and the application of professional skills. First of all, in the early stage of injection mold customization, mold designers must understand and evaluate the structure, size, parameters and other information of the product in detail. Only when it is confirmed that the existing mold structure can achieve mass production can we successfully proceed to the next step. Then, according to the evaluation results, the injection mold designer will design 3D engineering drawings, bulk drawings, split mold drawings, assembly drawings, EDM diagrams, electronic circuit diagrams and other drawings. These drawings will become an important basis for the subsequent production process.

The mold masters will communicate and confirm according to the drawings provided by the designer to ensure that there are no omissions and misunderstandings. Once it is confirmed, you can make a reservation for injection mold materials. If there is any objection or needs to be adjusted, the drawings must be modified in time to meet the requirements. When the injection mold material arrives, the mold engineer will inspect the material to ensure that it meets the needs of manufacturing and processing, and hand it over to the mold fitter for processing.

The heat-treated workpiece will be tested and analyzed by the mold engineer to ensure that there are no problems such as offsets or scars. Then carry out electrode processing and do a good job of data registration. Then carry out wire cutting processing, paying attention to the standards of each accessory processing, such as whether there is a matching gap between the insert hole and the thimble hole. Then there is the finishing of the injection mold. It is usually necessary to reserve the saving mold margin and record the size for detection at any time.

Production process and process of plastic mold customization

After EDM processing according to the drawing size, the surface of the flow channel is polished to increase its surface finish. Check before assembly, and do a good job of cleaning and anti-rust treatment to ensure the quality of the mold. Finally, the injection mold is assembled, tested and debugged. After confirming that there is no problem, a set of molds is considered to complete the whole production process.

The production process and process of customized injection molds require fine operation and strict control of all links. Only when each link is in place can high-quality injection molds be finally produced to meet the needs and requirements of customers.

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me. https://accounts.binance.com/en-IN/register?ref=UM6SMJM3

Requesting a reward, your tipping is my motivation

https://paypal.me/molddl?country.x=C2&locale.x=zh_XC