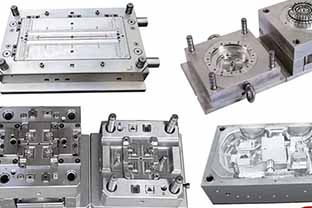

Plastic mold manufacturer, injection mold process

Plastic mold processing involves many processes, and there are clearly defined provisions in the production and processing process. In addition to the implementation according to the drawings and design scheme, it is important to understand the main contents of the plastic mold processing process. Now let’s see what the whole process includes. Each process can be further optimized to ensure the normal operation of the plastic mold in subsequent use.

1. design and material selection:

The three-dimensional design of the die is carried out by using CAD software, and the structure and size of the die are determined according to the structure and functional requirements of the product. According to the use of the mold, the expected service life, the type of plastic and other factors, select the appropriate mold steel.

2. material cutting:

The plastic mold needs to be cut before processing and manufacturing, including front mold material, rear mold material, insert material, preform, etc. According to different situations, it needs to be processed according to the actual needs. Xubang has done a very good job in the whole work process, and the cutting work is also very smooth. Only in accordance with this process, the plastic mold processing can be successfully completed.

3. frame opening:

Including front mold frame and rear mold frame. Due to the different types involved, it is necessary to consider the basic functions in the specific use process, and formulate the processing process in detail, so as to improve the use effect of plastic mold. Following the process will help the manufacturer to better control the product quality, make the mold more widely used in actual use, and basically avoid accidents.

4. rough cutting and sawing:

Cut large pieces of steel into appropriate sizes. Turning: the steel is processed to rough size by lathe.

5. finishing:

EDM uses the principle of EDM erosion to process the fine parts of the mold. CNC milling: use CNC milling machine for high-precision cutting.

6. grinding:

Use a grinder to grind the die surface to the required accuracy and finish.

7. mold assembly:

Assemble the mold core, sliding block, locating pin, etc. to ensure cooperative work.

8. mold test:

Test the mold in the actual production environment and check whether the mold works normally. Make necessary adjustments and optimizations for problems.

9. heat treatment:

The mould is hardened to enhance its durability and wear resistance.

10. mold adjustment and trimming:

According to the test results, the mold shall be adjusted and trimmed to meet the production requirements.

The above is the process of injection mold processing, and each step is crucial. Only by strictly following the process can the quality and performance of the plastic mold meet the expected standards.