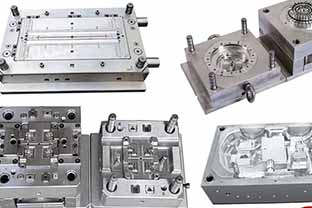

Plastic mold manufacturer, what is a high-precision plastic mold? What problems should be paid attention to when designing the mold?

High-precision plastic mold is a tool that plays a key role in the production of plastic products. It has higher design requirements and higher design complexity than ordinary molds. Before confirming the start of construction, it is necessary to ensure that all processes have been determined to avoid problems in the processing process. When designing high-precision plastic molds, you need to pay attention to the following issues:

1. Precision injection mold design engineers need to conduct a feasibility analysis of the plastic product drawings provided by the customer, determine the mold structure, and strictly stipulate the product design process. This is the most important step in the design process, which needs to be completed carefully to save subsequent working hours.

2. According to the precision injection mold design product, the drawing analysis is carried out, and the various materials required are prepared. Preparation according to the product expansion diagram can improve efficiency and accuracy, reduce errors, and help to complete the design work quickly.

3. Determine the opening direction and split line position of the high-precision plastic mold. Each plastic product needs to determine the mold opening direction and split line at the beginning of the design to minimize the core slider mechanism and reduce the impact of the split line on the appearance. After determining the mold opening direction, the product design should be consistent with the mold opening direction, so as to avoid pulling the core, reduce the seams, and extend the molding time.

4. Select the appropriate split line to avoid the upside-down phenomenon and improve the appearance and performance of the mold.

5. Adjust the drawing slope of the mold to avoid damage such as white edges, deformation and cracking on the top of the product. When designing deep cavity structure products, the slope of the outer surface should be greater than the slope of the inner surface to ensure uniform product wall thickness, while ensuring the material strength and product opening time.

6. Different plastics have different wall thickness ranges. If the wall thickness exceeds a certain value, it will lead to long cooling time, shrinkage and other problems. It is necessary to consider changing the product structure. Uneven wall thickness will lead to surface shrinkage, pores and welding wires. Reasonable use of reinforcement can increase the stiffness of the product and reduce deformation.

The design and manufacture of high-precision plastic molds requires highly specialized technology. Whether it is design or processing, it is necessary to find a professional mold design and development company to ensure high-quality production. In this regard, Donglai Mould Company can provide you with professional consultation and services. The design of high-precision molds is a highly technical project, which requires a rigorous attitude and exquisite technology to ensure product quality and production efficiency.