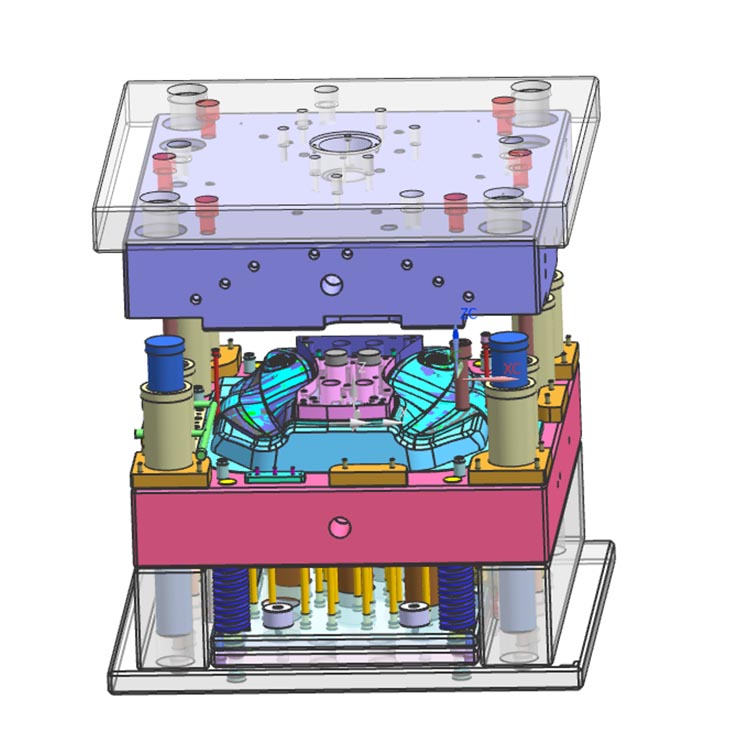

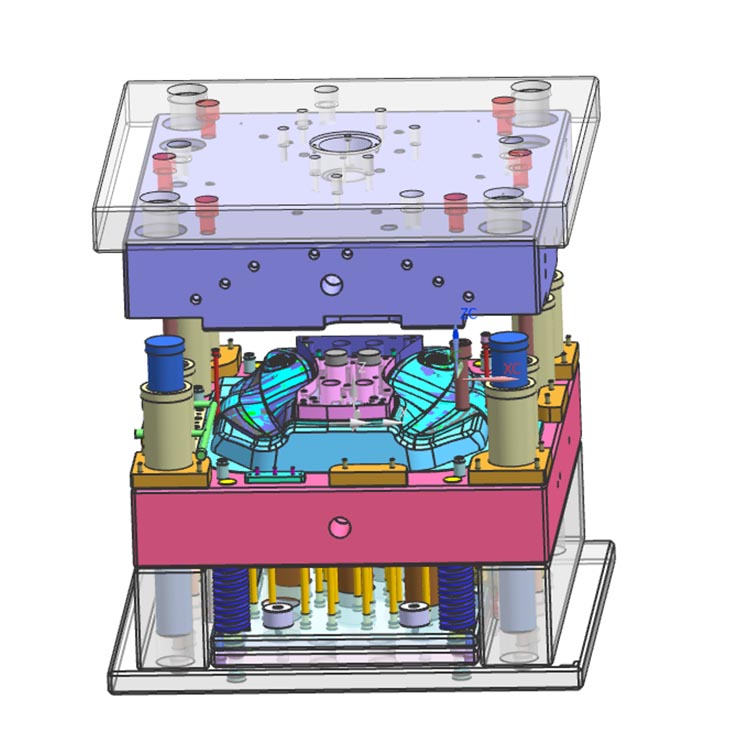

Overall layout of injection mold processing design, determination of mold type and mold cavity number, and systematic planning of gating system ejection method

Determining the primary layout of the mold type selecting the ideal mold layout lies in determining the necessary molding equipment, the desired number of cavities, and the ability to make the mold itself meet the technical skills and production economic needs of the plastic parts under certain reliable conditions. The skill demand for plastic parts is to ensure the shape, surface finish and dimensional accuracy of plastic parts. The economic demand of production is to make the cost of plastic parts low, the production efficiency high, the mold can work continuously, the service life is long, and the labor force is saved.

There are many factors that affect the mold layout and the single mold system, which are very messy:

① injection mold cavity layout design.

Injection mold cavity layout design is an important link in the production of injection mold, which determines the product quality and production efficiency. The following are the key points of the injection mold cavity layout design:

1. number of cavities: the number of cavities should be determined according to the production volume and size of the product. Generally speaking, the more the number of cavities, the higher the production efficiency, but the cost will increase accordingly.

2. cavity position: the cavity position should avoid product shrinkage, deformation and other problems as much as possible, and at the same time, the injection outlet of the injection molding machine and the inlet and outlet position of the mold should be considered.

3. cavity size: the cavity size should be determined according to the size and shape of the product. Generally speaking, the larger the cavity, the higher the production efficiency of the product, but it will also increase the cost.

4. cavity shape: the cavity shape should be determined according to the shape of the product. Generally speaking, the cavity shape should be as simple as possible for processing and maintenance.

5. cavity arrangement mode: the cavity arrangement mode should be determined according to the shape of the product and production efficiency. Generally speaking, the cavity should be evenly arranged as far as possible to improve production efficiency.

6. clearance between cavities: the clearance between cavities should be determined according to the size and shape of the product. Generally speaking, the clearance should be as small as possible to reduce the shrinkage and deformation of the product.

7. cooling mode of the cavity: the cooling mode of the cavity shall be determined according to the material and size of the product. Generally speaking, the cooling mode shall be as uniform as possible to improve the quality and production efficiency of the product.

Overall layout of injection mold processing design

According to the layout characteristics of the plastic parts, the requirements for dimensional accuracy, the size of the batch, the difficulty of making the mold, the cost of the mold, and the number and placement method of the cutting cavity. For the injection mold, the precision of plastic parts is grade 3 and 3a, the weight is 5g, the hardened pouring system is selected, and the number of cavities is 4-6; Plastic parts are of normal accuracy (level 4-5), molding materials are some crystalline materials, and the number of cavities can be 16-20; The weight of plastic parts is 12-16g, and the number of cavities is 8-12; For plastic parts with a weight of 50-100g, the number of cavities is 4-8. For amorphous plastic parts, the number of cavities is 24-48, 16-32 and 6-10. When the plastic parts are added continuously, the multi cavity mold is rarely used. For plastic parts with 7-9 grade accuracy, the maximum number of cavities is 50% more than that of plastics with 4-5 grade accuracy.

② Determine the parting surface. The orientation of parting surface shall be conducive to mold processing, exhaust, demoulding and molding operations, and the appearance quality of plastic parts.

③ Determine the injection mold pouring system (the shape, orientation and size of the main sprue, runner and gate) and the exhaust system (the method of exhaust, the orientation and size of the exhaust slot).

④ Select the ejection method (ejector rod, pipe jacking, push plate, combined ejection), and decide the side concave disposal method and core pulling method.

⑤ Determine the cooling and heating methods, the shape and orientation of the heating and cooling groove, and the equipment parts of the heating elements.

Overall layout of injection mold processing design

⑥ According to the mold material, strength accounting and experience data, determine the thickness and shape dimension of mold parts, shape layout and all connections, positioning and orientation of guide parts.

⑦ Determine the layout method of the primary molding parts and layout parts.

⑧ Consider the strength of each part of the injection mold, and calculate the operation scale of the molded parts. If the above questions are disposed of, the layout of the mold will be disposed of naturally. At this time, we will probably start to make the mold layout sketch to prepare for the formal drawing.

⑨ The injection mold drawing needs to be made according to the national drawing specification, but it also needs to contact the factory specification and the national irregular factory custom drawing method. Before drawing the general assembly drawing of the mold, the process drawing should be made and should meet the requirements of the part drawing and skill materials. The scale ensured by the next process shall be marked with “skill scale” on the drawing. If no other machining is carried out after forming in addition to repairing the burr, then the process drawing is completely the same as the part drawing. It is best to mark the part number, title, material, material shortening rate, drawing share, etc. under the process drawing. Usually, the process drawing is on the general assembly drawing of the mold. A. make the General Assembly layout drawing. Make the general assembly drawing with a 1:1 share as much as possible. First make it from the cavity, and draw the main view together with other views.