How is the easy damage of injection molds during the molding stage at Shenzhen Plastic Mold Factory caused

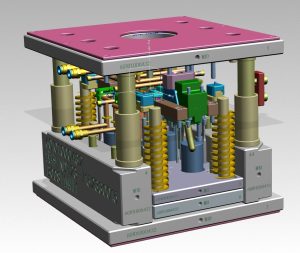

What is the reason for mold damage? Why are injection molding molds prone to damage? When the injection mold is in the assembly stage, it is subjected to relatively small external forces, but once installed on the injection molding machine, it will be affected by various external forces during the molding process

Can cause damage to the mold. Therefore, injection molds must have sufficient strength to withstand various external forces.

In general, molten resin flows towards the sprue and fills the cavity, but it must have sufficient injection strength to ensure smooth material flow into the sprue. Although the pressure is usually maintained for about 1 second, it can still cause minor impacts on the mold. In addition,

How is the easy damage of injection molds during the molding stage at Shenzhen Plastic Mold Factory caused

The push rod of the injection mold pushes out the shape of the molded product under the action of the push plate. If the push rod cannot be pushed or pulled smoothly, the operator usually applies greater force to complete the operation, which also requires the push rod to have a certain pressure bearing capacity.

Therefore, in order to ensure the normal operation of injection molds and extend their service life, it is necessary to pay attention to maintenance and upkeep work. Only by regularly inspecting and maintaining injection molds to ensure their strength and smooth operation can we effectively reduce the occurrence of damage and minimize the company’s losses.